This is designed to reliably transport OLED panels in environments such as vacuum, CDA, and N2 to prevent contamination

and degradation caused by environmental factors like gas, moisture, and particles in the atmosphere.

OLED Transfer

System

Competitive Advantages

-

Point 01

We handle a wide range of glass substrate sizes, from 2G to 8G.

-

Point 02

We possess extensive experience in manufacturing logistics equipment for multiple process environments, including Vacuum, N2, CDA, and Ambient Atmosphere.

-

Point 03

We simultaneously achieve both space efficiency and high productivity, capable of manufacturing logistics equipment for various layouts.

-

Point 04

We implement ultra-low moisture environments achieving 1 to 3 ppm (parts per million) or less.

-

Point 05

We apply contamination control technology meeting Clean Room standards.

Gas Exchange/Purification

Moisture Removal

Particle Removal

High-Density Glass Loading

OLED Transfer

System

We possess the optimal large-area panel transfer system technology for different atmospheres: N2·Vacuum·CDA Exchange/Purification N2, Vacuum, and Ambient Pressure

-

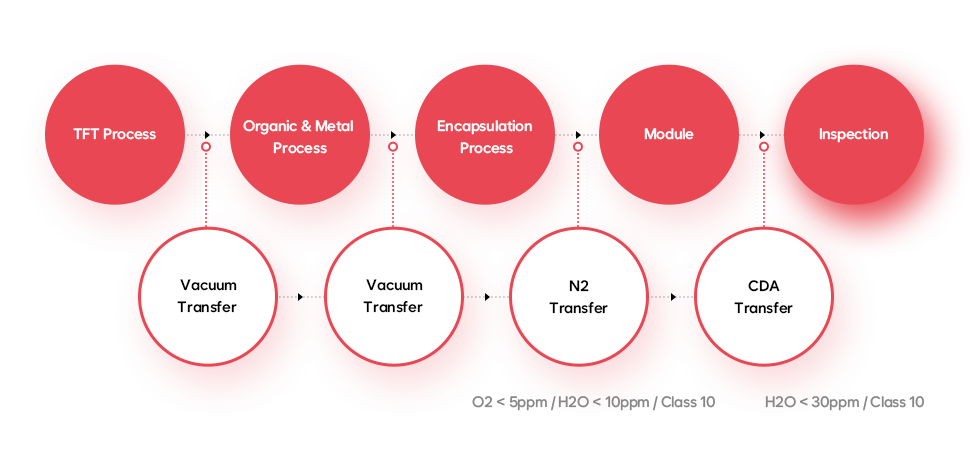

- OLED Display Panel Manufacturing Process

- Large-Area Panel Logistics Transfer

- Customized Environmental and Safe Transfer of Panels

- Vacuum · Nitrogen · CDA Exchange/Purification

Auto Transfer

System Process

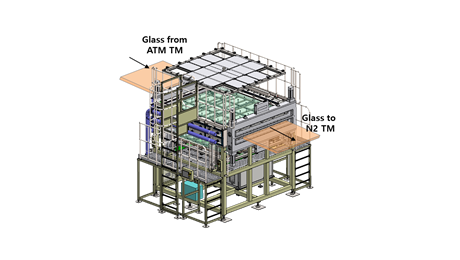

Transfer OLED Panel and Stock under Vacuum and N2 Environment

Equipment

Item

-

Units for OLED Panel MFG

Load-lock,, Glass Buffer, Mask Buffer, Shelf Chamber

X-axis TM, Rotation TM Chamber, Conveyor -

Experienced Chamber Size

Gen 2.5 / Gen 4.5 / Gen 6 / Gen 6.5 / Gen 8

-

Sales Record to OLED Panel MFG Line

Korea L Company - Multiple Recodes as 6G Half ~8G

China T Company - 6G Half Size* China Branch Office and Service Eng’r