SystemShuttle &

AMR for Smart

Factory

SystemShuttle

& AMR for

Smart Factory

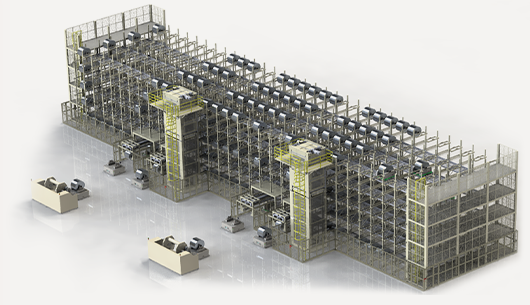

Total Automated Warehouse Solution Provider in the Prepared Secondary Battery Manufacturing Sector.

-

Pallet Shuttle & AMR System

-

Jumbo Roll Shuttle & AMR System

-

4-Way Multi-Directional Standardized Shuttle

-

Roll-Dedicated Shuttle

-

Roller Type AMR

-

Fork Type AMR

-

Roll-Dedicated AMR

-

Picking Robot

We are a specialized enterprise that builds intelligent logistics systems that continuously learn and optimize.

Shuttle System

The Shuttle System is one of the core pieces of equipment used in automated warehouses and smart factories. It functions to automatically store, retrieve, and transport various forms of cargo, such as pallets, boxes, and totes. The Shuttle Business involves the development, manufacturing, supply, and maintenance of this shuttle equipment.

4 - way SHUTTLE

- Low-Maintenance Design

- Extensive External Interface Capability

- Flexible Customization

AMR Business

The AMR (Autonomous Mobile Robot) Business implements smart automation in diverse fields, including logistics, manufacturing, and service industries, based on autonomous driving technology. The demand for smart factories and logistics automation is currently increasing, and it is growing rapidly, substituting the conventional conveyor and AGV markets.

General-Purpose AMR

- ROS-based SLAM Navigation

- General-purpose AMR featuring scalability and maintainability

- Intuitive web-based control software

Customizable AMR Solutions for Customer-Specific requirements

Autonomous Mobile Robot,

Self-Driving Robot

High-Payload Special-Purpose AMR

- 3D SLAM Navigation

- High-payload AMR of 1 ton or more

- Special-purpose AMR for Smart Factories

Cost-effective 'Special-Purpose AMR' such as High-payload (1T–100T), ForkLift type, etc.

Autonomous Mobile Robot,

Self-Driving Robot

TETRA

Series Specifications

-

Specification

SpecificationTETRA-EDU

- Dimension 492mm * 460mm * 246mm

- Max Payload 60kg

- Max Speed 1.5m/sec

-

Specification

SpecificationTETRA-DSV-S

- Dimension 485mm * 430mm * 380mm

- Max Payload 30kg

- Max Speed 2m/sec

-

Specification

SpecificationTETRA-DSV-SM

- Dimension 492mm * 460mm * 342mm

- Max Payload 50kg

- Max Speed 1.5m/sec

-

Specification

SpecificationTETRA-DSV-M

- Dimension 600mm * 490mm * 335mm

- Max Payload 100kg

- Max Speed 1.5m/sec

-

Specification

SpecificationTETRA-DSV-MH

- Dimension 800mm * 580mm * 300mm

- Max Payload 250kg

- Max Speed 1.5m/sec

-

Specification

SpecificationTETRA-DSV-H

- Dimension 868mm * 868mm * 274mm

- Max Payload 300kg(600kg)

- Max Speed 1.2m/sec(1m/sec)

OMARK

Series Specifications

-

Specification

SpecificationCD0200D-E

- Dimension 3012*1040*2140mm

- Max Payload 1650kg

- Max Speed 1.5m/sec

-

Specification

SpecificationFA0700D

- Dimension 2700*2000*700mm

- Max Payload 3500kg

- Max Speed 0.5m/sec

-

Specification

SpecificationGA0150D

- Dimension 2492*1392*938mm

- Max Payload 1500kg

- Max Speed 0.66m/sec

-

Specification

SpecificationGA0100D

- Dimension 2008*1308*1930mm

- Max Payload 1000kg

- Max Speed 0.8m/sec

-

Specification

SpecificationGA0050D

- Dimension 1560*800*670mm

- Max Payload 500kg

- Max Speed 0.8m/sec

AGV Business

Stabilized AGV in various forms.

- Diverse AGV and option solutions.

- Stabilized AGV in various environments.

- Extensive After-Sales Service support.

CarryBee

Series Specifications

-

Specification

SpecificationLow floor S type

- Dimension 840(L) x 350(W) x 350(H)mm / 1400(L) x 350(W) x 350(H)mm

- Max Payload 600kg

- Max Speed 0.8m/s

-

Specification

SpecificationLow floor M type

- Dimension 1390(L) x 350(W) x 272(H)mm / 2129(L) x 350(W) x 350(H)mm

- Max Payload 1500kg

- Max Speed 0.8m/sec

-

Specification

SpecificationLow floor H type

- Dimension 1670(L) x 480(W) x 290(H)mm / 2660(L) x 480(W) x 290(H)mm

- Max Payload 3500kg

- Max Speed 0.8m/sec

-

Specification

SpecificationLow floor L type

- Dimension 1945(L) x 350(W) x 170(H)mm / 2640(L) x 350(W) x 170(H)mm

- Max Payload 750kg

- Max Speed 0.8m/sec